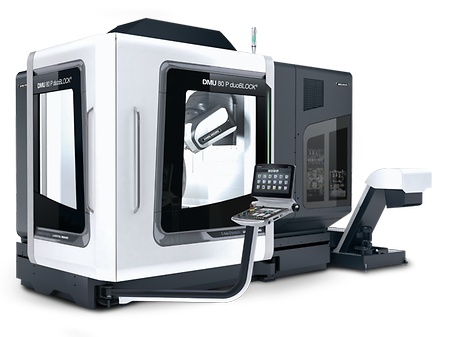

Sorry, this offer is no longer available on Exapro. DMG DMU 80P hi-dyn Machining center - 5 axis. DMG DMU 80 P Hi dyn Machining center - horizontal 1 / 6. Manufacturer: Dmg: Model: DMU 80 P Hi dyn: Year: 2001: Location: Germany: Category: Machining centers.

1 PRE OWNED DMG DMU 80P H.D / 5 AXIS UNIVERSAL MACHINING CENTER.

Videos Please call.

P:262.327.0800

DMG MORI DECKEL MAHO DMU80P hi-dyn 5-Axis universal machining center:

Machine was made at DECKEL MAHO Pfronten in Pfronten, Germany

Build date: 08/2001

First installed new in the USA: /2002

Design Concept

This machine is TWO machines in one because of the universal milling head that swivels from horizontal to vertical position and vice versa. This allows complete machining in one set-up for up to 5-sides and 5-axes simultaneous

Dmg Dmu 80 Monoblock

machining. B-Axis head swivels 187.60 degrees and C-Axis table rotates 360 degrees.

Control

HEIDENHAIN MillPlus iT 3-D control with Ethernet connection & electronic handwheel

Working Range

X axis (longitudinal)…………………………… 31.5″ (800 mm)

Y axis (transverse)……………………………. 27.6″ (700 mm)

Z axis (vertical)………………………………. 23.6″ (600 mm)

Maximum Workpiece Dimensions

Maximum workpiece diameter………………………. 36.2″ (920 mm)

Maximum workpiece height………………………… 39.4″ (1,000 mm)

Maximum workpiece weight……………………. 1,760 lbs (800 kg)

4th Axis NC Rotary Table (C-Axis)

Clamping surface… 35.4″ diameter x 24.8″ (900 mm diameter x 630 mm front to back)

Maximum table load (centered)………………… 1,760 lbs (800 kg)

Resolution of measuring system……………………… 0.001 degrees

5th Axis NC Controlled Universal Milling Head (B-Axis)

This machine is equipped with a universal milling head that swivels from horizontal to vertical position and vice versa. In addition the milling head has a controlled B-Axis. Swivel angle from vertical position 0 deg

Dmg Dmu 200p

to the left -7.30 degrees (in direction of tool magazine) and to the right to horizontal position +180.30 degrees for a total 187.60 degrees swivel range. This allows complete machining in one set-up for up to 5-sides and 5-axes simultaneous machining.

Main Drive

Type……………………………………… AC controlled/digital

Power 40% duty cycle (S3)…………………………. 37.5 hp (28 kW)

Power 100% duty cycle (S1)…………………………. 25.5 hp (19 kW)

Spindle speed range………………………………. 20-18,000 rpm (new spindle by DMG in 2011)

Acceleration/Deceleration……………………………. 2.2 seconds

Number of gear steps………………………………………. None

Maximum spindle torque 40% duty cycle…………. 89.2 ft/lb (121 Nm)

Maximum spindle torque 100% duty cycle…………. 60.48 ft/lb (82 Nm)

Spindle bearing diameter front……………………… 3.15″ (80 mm)

Spindle bearing diameter rear………………………. 2.36″ (60 mm)

Welcome to James' website for third grade! Third Grade -James -TES. Home Homework Sight Words Art Resources Reading Dip Sports Contact Grammar practice days spelling Practice. Powered by Create your own unique website with customizable templates. Find eer and ear words lesson plans and teaching resources. Quickly find that inspire student learning. Lesson Planet provided me with various worksheets to supplement lessons for my multi-grade class. Members since 2013. You are doing an excellent job by helping me find a wide range of materials for core subjects. Moreno Valley, CA. Failure to submit an EER is a Major (Class 2) violation which may result in a penalty of $3000 in the first year and $5000 for each additional year until the EER is submitted to the department. The Department will not accept any outstanding EER submission if outstanding penalties are not paid in full. EER Violation Challenge Form. Eer earthird grade james testing. Welcome to James' website for third grade! Home Sight Words Art Resources Reading Dip Contact Sports day School Tour Practice. Powered by Create your own unique website with customizable templates. Welcome to James' website for third grade! Third Grade -James -TES. Home Homework Sight Words Art Resources Reading Dip Sports Contact Grammar practice days spelling Sight. Week 15 er ir ur. Week 16 or oar ore.

Spindle taper…………………………………………. CAT 40

Feed Drives

Type………………………………………. Brushless AC/Digital

Feed rate………………………… 0.04″-590 IPM (1-15,000 mm/min)

Rapid feed (X/Y/Z)…………………………. 1,575 IPM (40 m/min)

Acceleration…………………………………………… 5 m/s-2

Feed power (X/Y/Z)………………………………………. 10 kN

Ballscrew (X/Y/Z)…………………………… 40×20/40×20/40×20 mm

60 Position Tool Changer

Magazine type……………………. Horizontal chain, double gripper

Number of pockets…………………………………………… 60

Maximum tool weight………………………………. 22 lb (10 kg)

Maximum tool diameter with no empty neighboring pockets 3.94″ (100 mm)

Maximum tool diameter with empty neighboring pockets…. 6.3″ (160 mm)

Maximum tool length………………………………. 13.8″ (350 mm)

Tool change time………………………. Approximately 5.5 seconds

External Flood Coolant

External coolant jets pressure…………………. 21.7 PSI (1.5 bar)

External coolant jets flow rate………………. 10.6 gpm (40 l/min)

Chip conveyor pump output pressure……………… 21.7 PSI (1.5 bar)

Chip conveyor pump output flow rate……………. 15.8 gpm (60 l/min)

Coolant tank capacity…………………………. 160 gallon (600 l)

Coolant Thru The Spindle

Pump output……………………………………. 6 gpm (23 l/min)

Pump pressure…………………………………. 580 PSI (40 bar)

HEIDENHAIN glass scales X/Y/Z Axes direct path measuring system

Input Resolution………………………………………. 0.001 mm

HEIDENHAIN rotary encoders B/C Axes direct path measuring system

Input Resolution………………………………………. 0.001 mm

Equipped With

Fully enclosed protection cabin

Production Package consisting of:

Coolant tank 158 gallon (600 l)

Automatic coolant cleaning through paper band filter

580 PSI (40 bar) coolant thru the spindle centre (Form AD)

Rotating clear-view window (in cabin window)

Control

HEIDENHAIN MillPlus iT 3-D control with Ethernet connection & electronic handwheel

Working Range

X axis (longitudinal)…………………………… 31.5″ (800 mm)

Y axis (transverse)……………………………. 27.6″ (700 mm)

Z axis (vertical)………………………………. 23.6″ (600 mm)

Maximum Workpiece Dimensions

Maximum workpiece diameter………………………. 36.2″ (920 mm)

Maximum workpiece height………………………… 39.4″ (1,000 mm)

Maximum workpiece weight……………………. 1,760 lbs (800 kg)

4th Axis NC Rotary Table (C-Axis)

Clamping surface… 35.4″ diameter x 24.8″ (900 mm diameter x 630 mm front to back)

Maximum table load (centered)………………… 1,760 lbs (800 kg)

Resolution of measuring system……………………… 0.001 degrees

5th Axis NC Controlled Universal Milling Head (B-Axis)

This machine is equipped with a universal milling head that swivels from horizontal to vertical position and vice versa. In addition the milling head has a controlled B-Axis. Swivel angle from vertical position 0 deg

Dmg Dmu 200p

to the left -7.30 degrees (in direction of tool magazine) and to the right to horizontal position +180.30 degrees for a total 187.60 degrees swivel range. This allows complete machining in one set-up for up to 5-sides and 5-axes simultaneous machining.

Main Drive

Type……………………………………… AC controlled/digital

Power 40% duty cycle (S3)…………………………. 37.5 hp (28 kW)

Power 100% duty cycle (S1)…………………………. 25.5 hp (19 kW)

Spindle speed range………………………………. 20-18,000 rpm (new spindle by DMG in 2011)

Acceleration/Deceleration……………………………. 2.2 seconds

Number of gear steps………………………………………. None

Maximum spindle torque 40% duty cycle…………. 89.2 ft/lb (121 Nm)

Maximum spindle torque 100% duty cycle…………. 60.48 ft/lb (82 Nm)

Spindle bearing diameter front……………………… 3.15″ (80 mm)

Spindle bearing diameter rear………………………. 2.36″ (60 mm)

Welcome to James' website for third grade! Third Grade -James -TES. Home Homework Sight Words Art Resources Reading Dip Sports Contact Grammar practice days spelling Practice. Powered by Create your own unique website with customizable templates. Find eer and ear words lesson plans and teaching resources. Quickly find that inspire student learning. Lesson Planet provided me with various worksheets to supplement lessons for my multi-grade class. Members since 2013. You are doing an excellent job by helping me find a wide range of materials for core subjects. Moreno Valley, CA. Failure to submit an EER is a Major (Class 2) violation which may result in a penalty of $3000 in the first year and $5000 for each additional year until the EER is submitted to the department. The Department will not accept any outstanding EER submission if outstanding penalties are not paid in full. EER Violation Challenge Form. Eer earthird grade james testing. Welcome to James' website for third grade! Home Sight Words Art Resources Reading Dip Contact Sports day School Tour Practice. Powered by Create your own unique website with customizable templates. Welcome to James' website for third grade! Third Grade -James -TES. Home Homework Sight Words Art Resources Reading Dip Sports Contact Grammar practice days spelling Sight. Week 15 er ir ur. Week 16 or oar ore.

Spindle taper…………………………………………. CAT 40

Feed Drives

Type………………………………………. Brushless AC/Digital

Feed rate………………………… 0.04″-590 IPM (1-15,000 mm/min)

Rapid feed (X/Y/Z)…………………………. 1,575 IPM (40 m/min)

Acceleration…………………………………………… 5 m/s-2

Feed power (X/Y/Z)………………………………………. 10 kN

Ballscrew (X/Y/Z)…………………………… 40×20/40×20/40×20 mm

60 Position Tool Changer

Magazine type……………………. Horizontal chain, double gripper

Number of pockets…………………………………………… 60

Maximum tool weight………………………………. 22 lb (10 kg)

Maximum tool diameter with no empty neighboring pockets 3.94″ (100 mm)

Maximum tool diameter with empty neighboring pockets…. 6.3″ (160 mm)

Maximum tool length………………………………. 13.8″ (350 mm)

Tool change time………………………. Approximately 5.5 seconds

External Flood Coolant

External coolant jets pressure…………………. 21.7 PSI (1.5 bar)

External coolant jets flow rate………………. 10.6 gpm (40 l/min)

Chip conveyor pump output pressure……………… 21.7 PSI (1.5 bar)

Chip conveyor pump output flow rate……………. 15.8 gpm (60 l/min)

Coolant tank capacity…………………………. 160 gallon (600 l)

Coolant Thru The Spindle

Pump output……………………………………. 6 gpm (23 l/min)

Pump pressure…………………………………. 580 PSI (40 bar)

HEIDENHAIN glass scales X/Y/Z Axes direct path measuring system

Input Resolution………………………………………. 0.001 mm

HEIDENHAIN rotary encoders B/C Axes direct path measuring system

Input Resolution………………………………………. 0.001 mm

Equipped With

Fully enclosed protection cabin

Production Package consisting of:

Coolant tank 158 gallon (600 l)

Automatic coolant cleaning through paper band filter

580 PSI (40 bar) coolant thru the spindle centre (Form AD)

Rotating clear-view window (in cabin window)

About usshortnotesg.c.e ol. Chip conveyor with interval control

Dmg Dmu 80 P Hi Dynminew Hi

Preparation (only) for RENISHAW MP10 infrared parts measuring probe

BLUM Laser tool measuring-tool length, diameter & broken tool detection

Automatic retraction of the measuring unit in a protected housing.

Tool length and diameter measuring in horizontal/vertical position.

Spray pistol with pump, 14.5 PSI/10.4 gallon/min pump performance

In Stock Under Power EMT Shop Hartland Wisconsin.

P:262-327-0800

SPECIFICATIONS ARE SUBJECT TO VERIFICATION.

SUBJECT TO AVAILABILITY, AND TERMS AND CONDITIONS

FOLLOWING, WE OFFER FOR YOUR CONSIDERATION

Dmg Dmu 210

European Machine Tools

Dmg Dmu 70

SHOP & SHOW ROOM

Dmg Dmu 80

Hartland 53029, Wisconsin U.S.A

SPECIALIST IN 5 AXIS MACHINE TOOLS

Dir: 262-327-0800